While they have used WORKNC, from Vero Software, to machine their molds for at least 15 years, VISI…also from the Vero stable…is a relatively new investment. The machines mean the company has a locking force of between 22 and 100 tonnes, giving them the ability to supply molded plastic parts up to 230 grams. While making tools for plastic injection molders remains an important part of their business, they set up their own molding operation in 2000, and now have seven molding machines – two Boys, two Battenfelds and three Arburgs. Maurice bought into the business in 1982, eventually taking sole ownership. Nowadays it is run by just four people: Maurice Chapman, his two sons Mark and Stephen, and Stephen’s wife Tracy. The company was established as a subcontract mold maker in 1957, moving to their current 3,500 square foot premises in Northamptonshire, in 1970 with ten employees. Mark Chapman, Company Secretary and Moldmaker “CAD designers are producing increasingly more complex parts, but VISI gives us the ability to meet those demands quickly and easily.

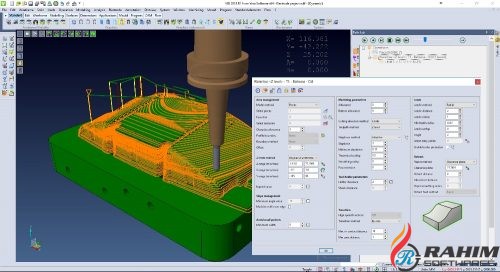

Designing their molds in VISI, and machining them with toolpaths generated by WORKNC, ensures that the tight tolerances they need to achieve are met first time, every time. Those are the words of Mark Chapman, company secretary and moldmaker at family-run business Sharnold Ltd. But when we invested in VISI that immediately came down to a couple of days. “Some complex mold tools used to take me nearly a week to design. Vero Software offers dedicated solutions that eliminate the links between varying software suppliers and the solid-to-surface or CAD/CAM geometry conversions required by traditional systems.– And WORKNC Machining Code Is Ready In Moments Industry-specific applications for plastic injection tool design, including material flow analysis and progressive die design with step-by-step unfolding, provide the toolmaker with unsurpassed levels of productivity. It offers a unique combination of applications, fully integrated wireframe, surface and solid modeling, and comprehensive 2D, 3D, and 5-axis machining strategies with dedicated high speed routines. VISI is acknowledged as one of the worlds leading PC-based CAD/CAM solutions for the mold & die industries.

0 kommentar(er)

0 kommentar(er)